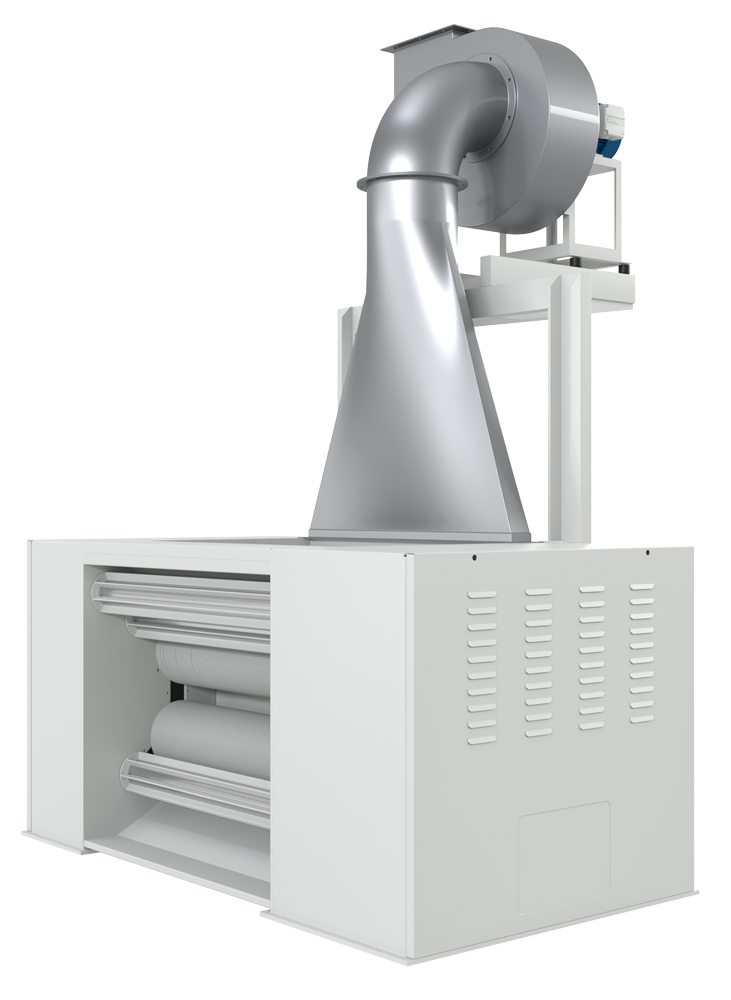

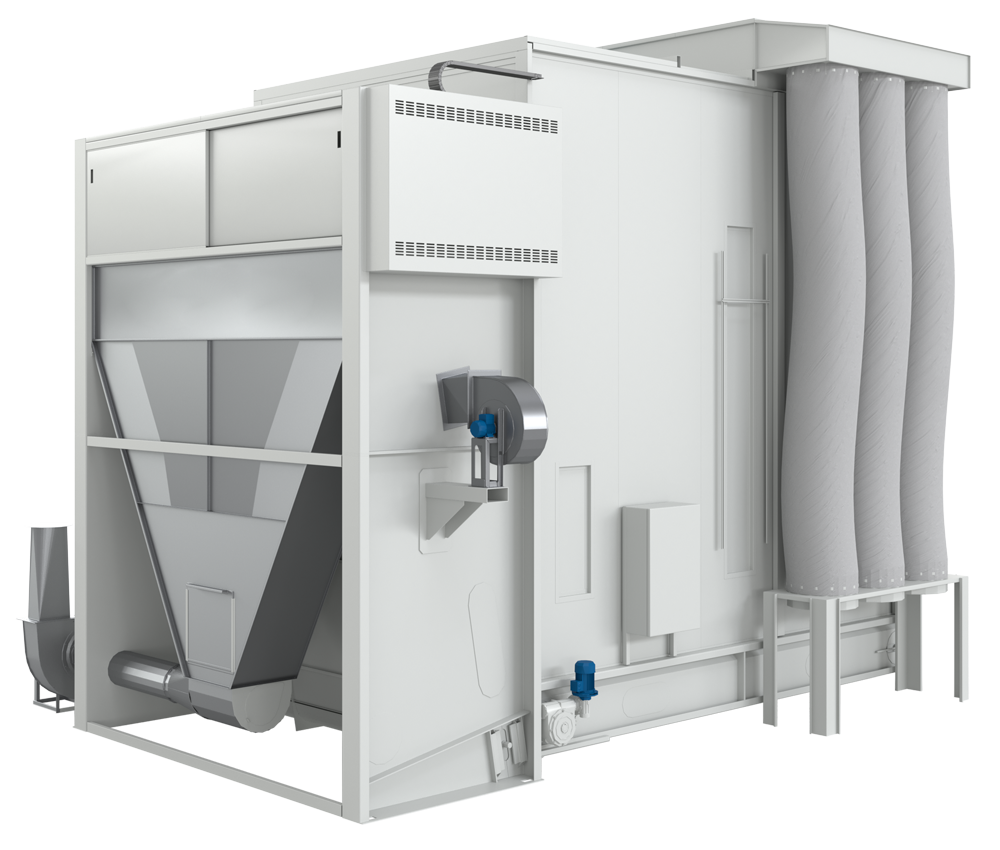

Bale Opener

Designed for the opening of the compressed bales of all kinds of fibers, natural, synthetic and recycled, the Bale Opener is equipped with an automatic weighing scale installed on load cells for high blending accuracy and a delivery conveyor-belt.

Weighing

Electronic weighing scale installed on load-cells.The weighing ranges from 2 to 6 per minute with a fault tolerance no more than 1%.