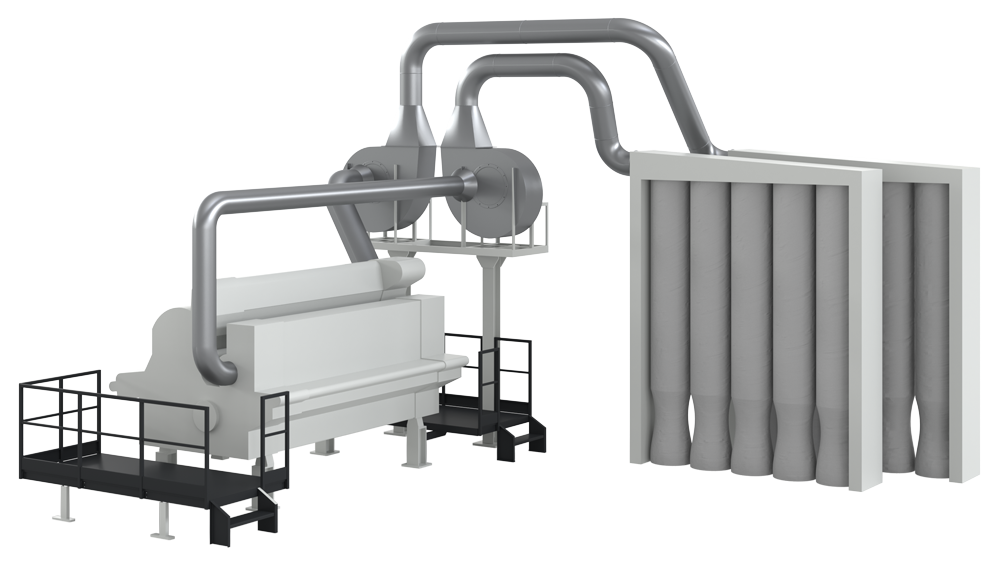

Airlay-S

The Airlay-S is designed for the aerodynamic forming of the web. Its special Patented technical configuration allows to lay the fiber along the web thickness in a S-shape, strongly increasing the longitudinal strength of the product. Especially suitable for insulation pad manufacturing, the Airlay-S processes all kinds of fibers, shoddy, natural, mineral and synthetic whether they are short or long, offering a wide production range also in automotive, filtration, furniture and building industry. Optionally equipped with a double feeding unit the Airlay-S can blend fiber with non-fibrous matter like polyurethane foam, wood chips and other material. The Airlay-S can process any kind of fibers with a maximun length of 100 mm and a minimum granulometry of 2 mm. PET, PP and Bico fibers can only be used as binder (no powder components like EVA or phenolic resins).

Double Feeding

The double pneumatic feeding unit ensures an excellent regularity of transversal density and allows use of a wide range of physically immiscible fibrous and non-fibrous compositions and mixtures like fiber with rice husk, polyurethane foam, wood chips, grinded polystyrene, grinded corianders of resin-bonded nonwoven.

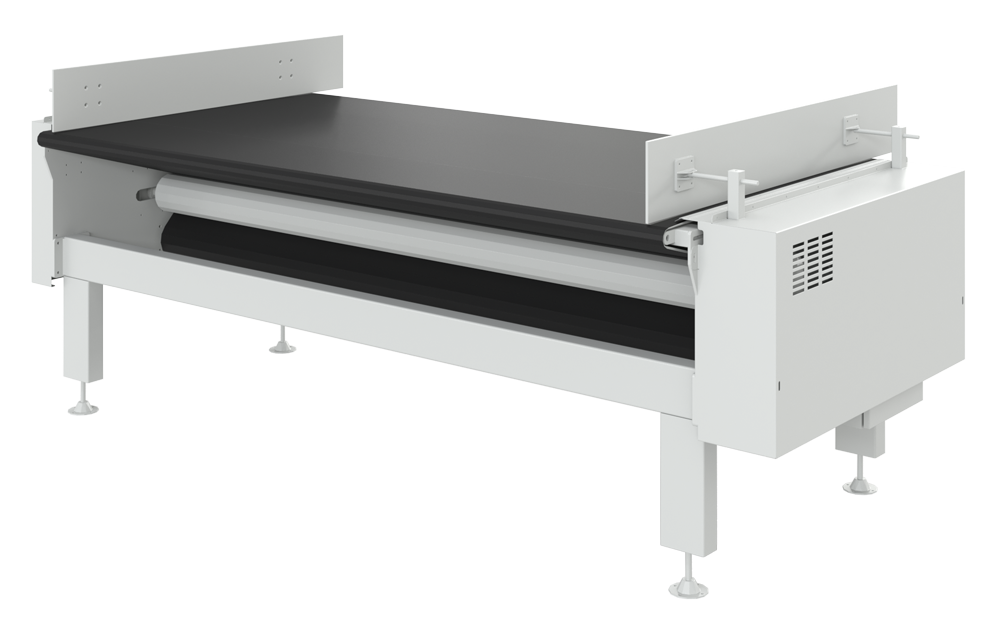

Web forming

Product formation takes place in a depressurized room adjustable from 20 mm to 300 mm allowing production of a wide range of products with different basic weights and densities.