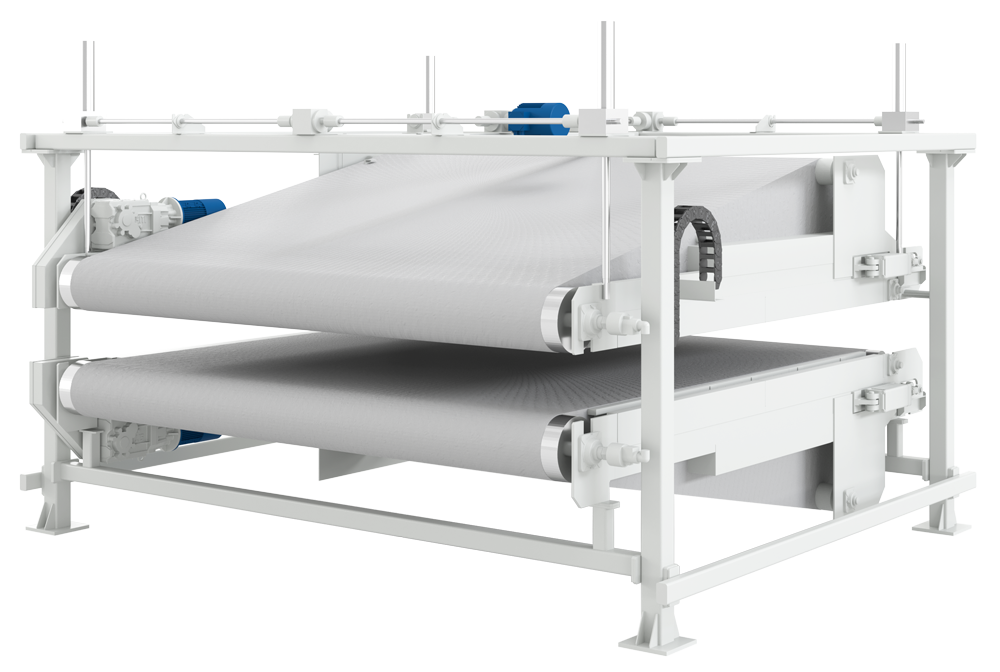

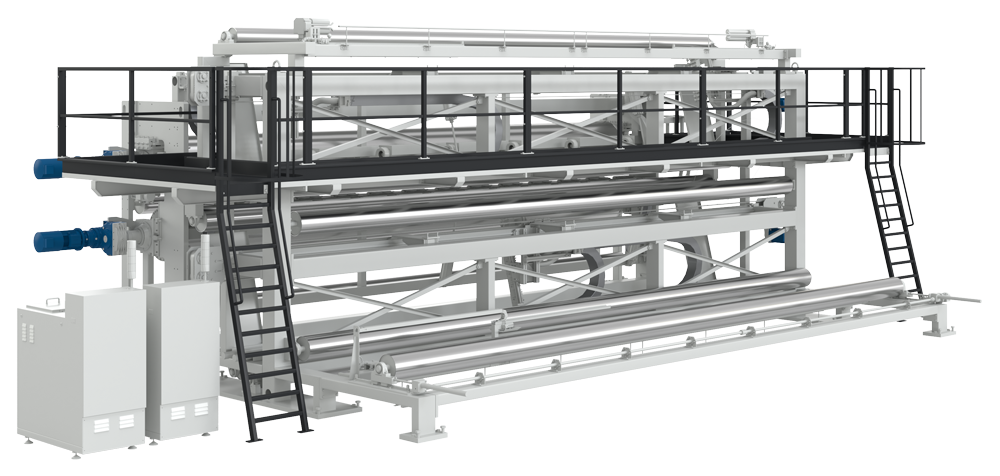

Pad Smoother

Mainly designed for the calibration and surface smoothing of thermal bonded nonwoven, the Pad Smoother is also used as a laminating unit to laminate the polyester pad with a polyester film without the need of glue or low melting powder. Essential product features are achieved in the field of construction and building industry. The particular design allows easy remove and replacement of the double Teflon belt drastically reducing the machine down-time.