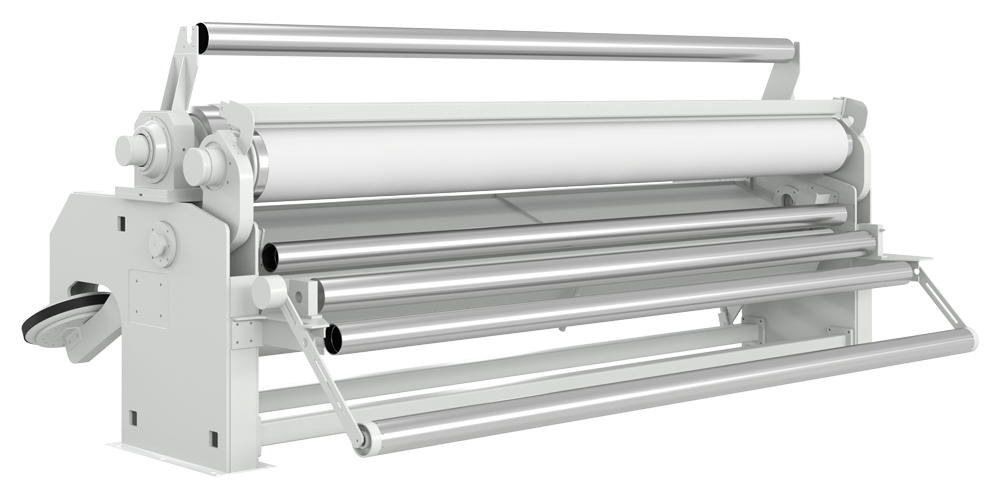

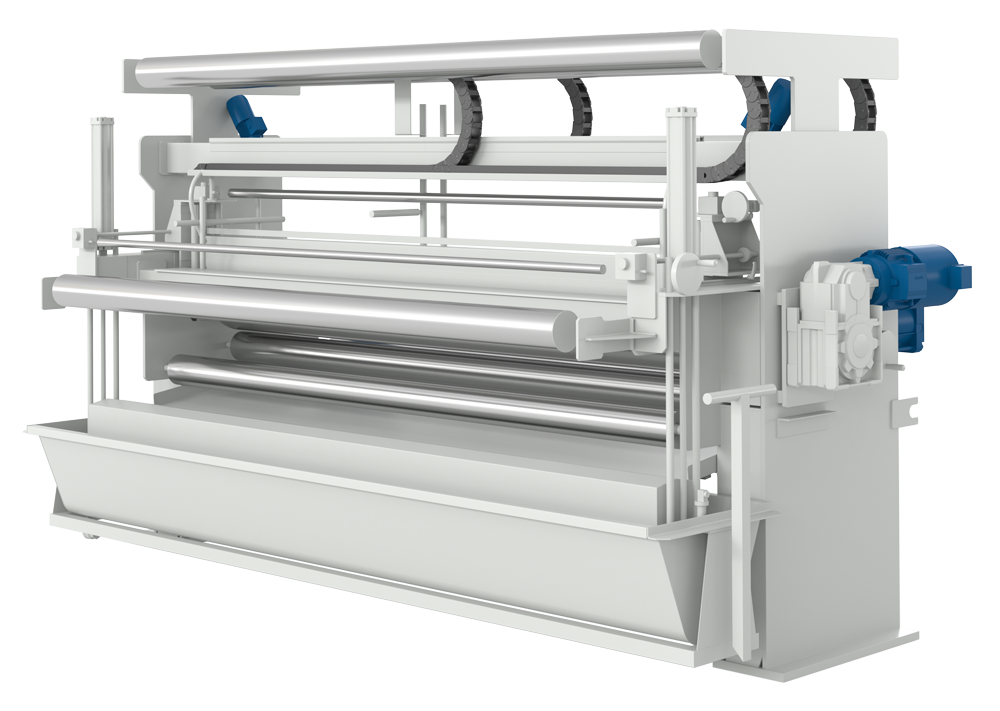

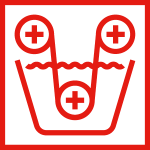

Padder

With a roller up to 8.000 mm wide, the 2-roller Ramina Padder is designed for the impregnation of nonwoven with different chemicals like resin, foam and other solutions. The squeezing of nonwoven is commensurate with the desired final concentration of binder on the product. The control of roller deflection allows homogeneous impregnation along the product width for every pressure distribution. The machine design allows fast maintenance operation thanks to the special roller disassembling and cleaning systems, reducing downtime to a minimum.