Spunbond, meltblown and composite lines

download complete

Spunbond

Dosing of polymer,

with the possibility

to mix them with

pigments and

master batch

Extrusion of the

melted polymer

and filtration

Spinning of the melt

through one spinning

beam into continuous

filaments

Filament quenching

and stretching with

a diffuser

Uniform distribution

of filaments on the

main conveyor

forming web

Meltblown

Dosing of polymer,

with the possibility

to mix them with

pigments and

master batch

Extrusion of

the melted polymer

and filtration

Spinning of the melt

through one spinning

beam into continuous

filaments

Filament cooling

Uniform distribution

of filaments on the

main conveyor forming

web

Spunbond

Repeat previous

Spunbond process

Thermobonding

by calendering to

stabilize the product.

This phase ensure

the texture and can

also create specific

patterns

Cutting of nonwoven

and roll winding

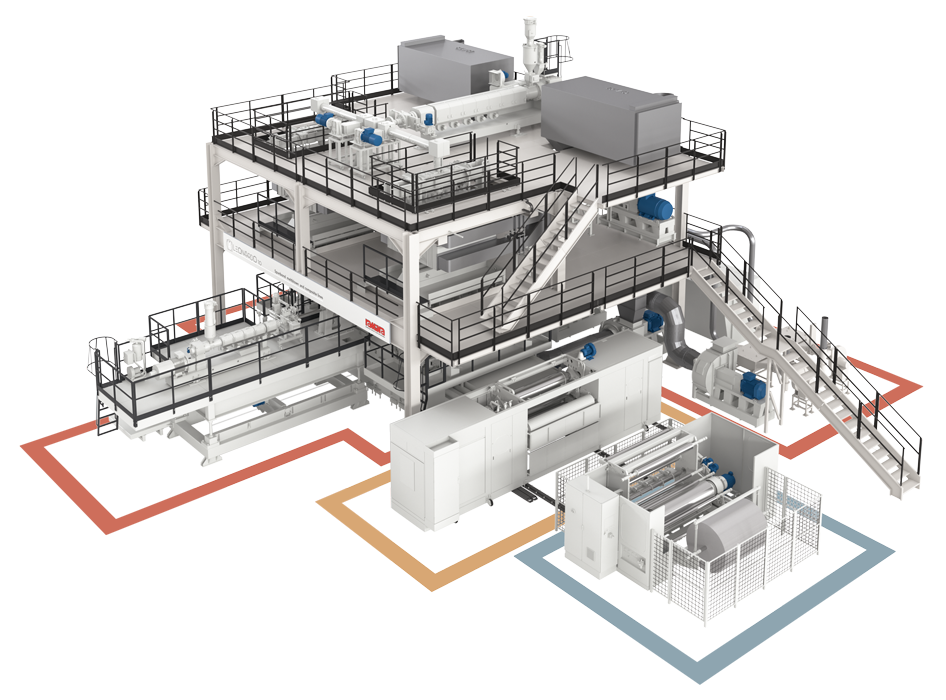

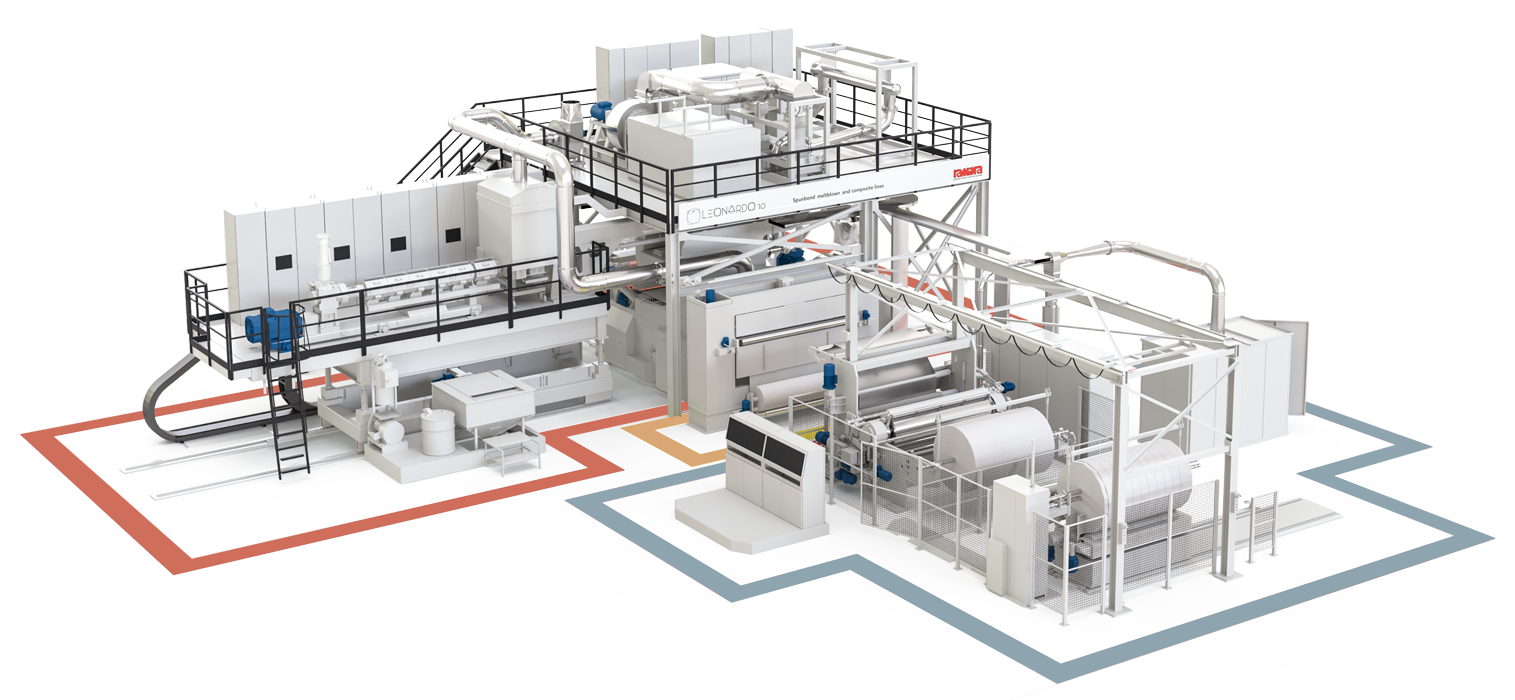

Leonardo 1.0 - Spunbond and SMS technology:

S, SS, SSS, SSSS

SMS, SMMS, SMMMS, SMMMMS, SSMS, SSMMS, SSMMMS, SSMMMMS, SSMMSS, SSMMMSS, SSMMMMSS

Max.

200 Kg/h/m

Max.

Max.

2.400 mm

3.200 mm

4.200 mm

5.200 mm

| Spunbond | Um | Leonardo 1.0 |

|---|---|---|

| Max. Production | kg/h/m | 200 |

| Filament Titer | den | 1,3 - 1,8 |

| Basic weight | gsm | 8 - 150 |

- Reduce down-times by patented system

- Perfect air distribution homogeneity

- Low product scrape

- Very fast time for weight and color changing

- Industry 4.0 technology

- Predictive maintenance operations

- Line control by tablet and smart-phone

Dedicated Storing

and Dosing Units

of polymer and

masterbatch are

needed for the

automatic feeding

of the extruder

with a volumetric

or gravimetric system.

A suitable mono-screw

Extruder for the melting

of the polymer is heated

by electrical resistors

and it is supplied with

an Exchange Filter for the

removal of eventual

impurities that could

damage the subsequent

process equipment.

The melt is carried

by a Metering Pump

toward the Transfer

Line and then toward

an electrically heated

Meltblown Spinning Beam

containing several

hundred small capillars

for the continuous

filaments extrusion.

The extruded filaments

converge in a stream of

hot air to extremely reduce

the fine diameter fibres

that are attenuated and

subsequently blown onto

the main conveyor belt

for the forming of the

meltblown web.

A cooling calender

reduces the meltblown

thickness.

The electrostatic bars

improve the filtration

efficiency of the material

that it finally wound

up and slit in the SW Winder.

Leonardo 1.0 - Meltblown technology:

Max.

50 Kg/h/m

Max.

120 m/min

Max.

2.400 mm

3.200 mm

4.200 mm

5.200 mm

| Meltblown | Um | Leonardo 1.0 |

|---|---|---|

| Max. Production | kg/h/m | 50 |

| Filament Titer | μm | < 1 - 5 |

| Basic weight | gsm | 10 - 400 |

Leonardo 1.0 is quick

The production reaches up to 1.000 meters of fabric per minute. A quicker production without compromising the quality.

Leonardo 1.0 is efficient

Leonardo 1.0 technology allows a fast cleaning and maintenance process to reduce downtimes. This is a big step forward and ensures a high level of productivity. Leonardo 1.0 saves customers’ time and increases their revenues. The production ranges from 200 kg per hour per linear meter of spunbonded fabrics, to 50 kg per hour per linear meter for meltblown fabrics.

Leonardo 1.0 is green

Ramina pays close attention to minimize the impact of its lines on the environment. For this reason the high productivity of Leonardo 1.0 goes hand-in-hand with energy saving technology.

Leonardo 1.0 is versatile

It opens an array of opportunities. Spunbond, meltblown or composite: the choice is yours. Leonardo 1.0 gives you the technology to adapt your production according to the product you need to produce. The line can be fitted with multiple technologies while guaranteeing a stable production process and uniform results.

Applications

Discover our other turn-key plants