Geocomposite

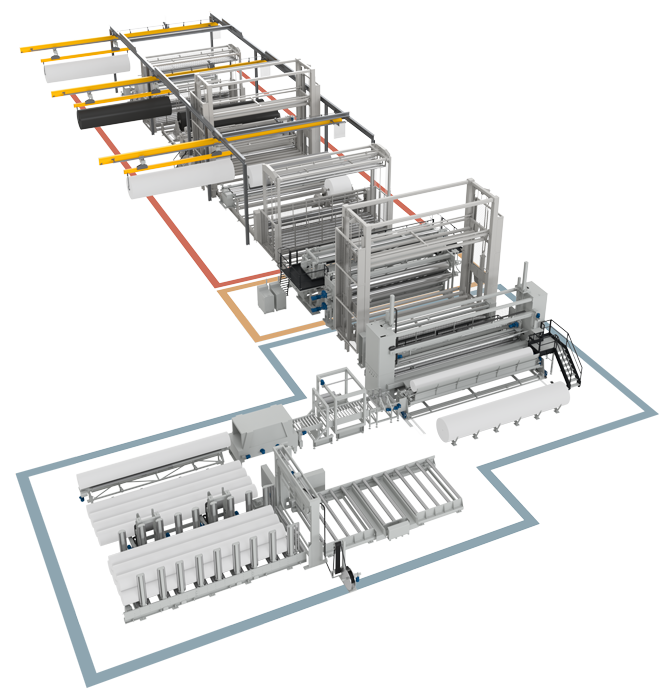

Lamination line

Ramina designs and manufactures lamination lines for geocomposites. Thanks to its technology it is possible to laminate up to two layers of PP geotextile with one layer of Geomembrane, Geogrid, HDPE, and other materials. The Geocomposite line can be adapted to laminate other auxiliary materials in order to meet customers’ needs and create a personalized product.

download complete

Unwinding of lower

geotextile layer and

its accumulation.

Unwinding of

membrane/geogrid

central layer and

its accumulation

Unwinding of

upper geotextile

layer and its

accumulation

Double lamination unit:

hot melt glue distribution

(for HDPE, PVC, etc.)

or IR heating (only for

geogrid and geomembrane).

Calendering lamination

of the newly-formed

geocomposite

Accumulation

of geocomposite

Cutting of

geocomposite

and roll winding

Automatic wrapping

of the roll with

shrinking film

Automatic palletizing

and strapping of

the rolls

Product width:

Max.

7.000 mm

Working speed:

Max.

15 m/min

Raw material

Layer 01: PP geotextile.

Layer 02: Geomembrane, Geogrid, Geomat, HDPE, LLDPE, PVC, Aluminium.

Layer 03: PP geotextile.

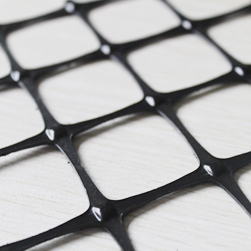

Geocomposite geotextile

+ geomat + geotextile

Geocomposite geotextile

+ geogrid

| Working width: | 7.200 mm |

| Roll diameter: | up to 1.500 mm |

| Sewing machine: | manual/automatic |

| Centering system: | manual/automatic |

Applications

Discover our other turn-key plants

Spunbond, meltblown and composite lines

Airlay S line

Thermobonding

line

Geosynthetics

clay liner

Needling

line

Spunbond roofing

and Geotextile line

Previous

Next