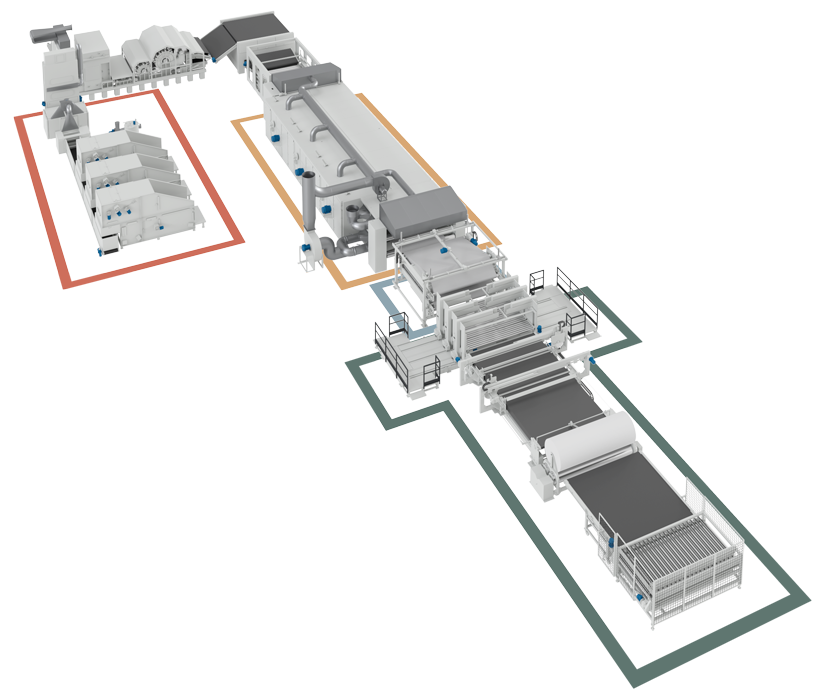

Thermobonding

line

download complete

Opening, dosing and

blending of the fibers

Carding of the fibers.

Fibers are arranged

in the machine direction

to create a web

Crosslapping of the web.

The web is layered to increase

the cross directional strength

of the fabric and improve

its uniformity. It ensures weight

accuracy and defines the width

of the final product

Drafting of the web. It

ensures the desired MC/ CD

ratio and consequently

the right tensile strength

and elongation of the

final product

Thermobonding through

a wadding tunnel oven

with an internal cooling unit.

It gives the desired thickness

to the final product

Pad smoother, designed for

the calibration and surface

smoothing of the pad.

It can be used to laminate

the pad with film or other

materials without adding

glue or low melting powders

Slitting and high-precision

flying cross cutting for pads

up to 250 mm

Roll winding

or pad stacking

| Production capacity: | max. 700 kg/h |

| Working width: | 1.500 mm |

| Fiber length: | 38 - 100 mm |

| Fiber denier: | 1 - 100 Dtex |

| Weighing per minute: | 2 - 6 |

| Weighing error: | max. 1% |

| In-line bale opener: | max. 5 |

Applications

Discover our other turn-key plants