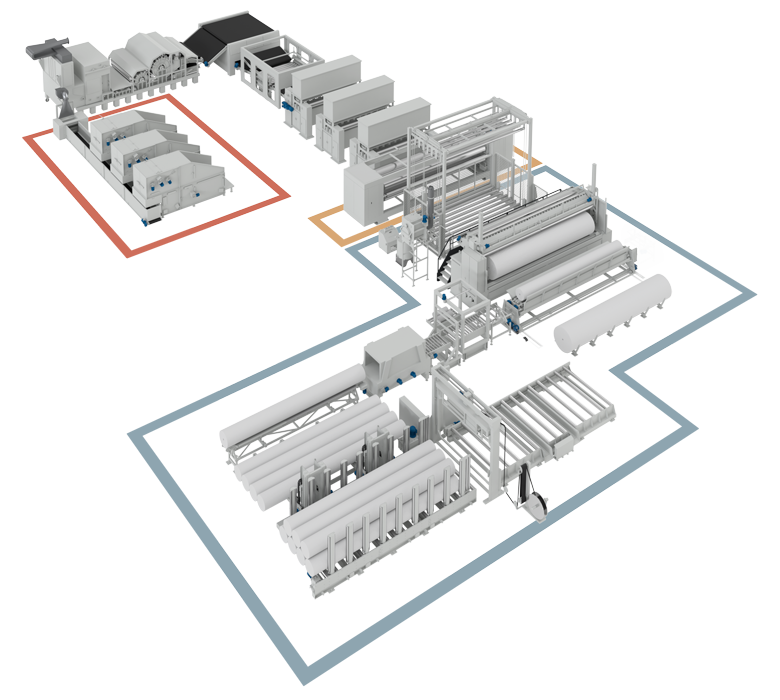

Needling

line

download complete

Opening, dosing

and blending of

the fibers

Carding of the fibers.

The fibers are arranged

in the machine direction

to create a web

Crosslapping of the

web. The web is layered

to increase the cross

directional strength

of the fabric and improve

its uniformity. It ensures

weight accuracy and defines

the width of the final product

Drafting of the web. It ensures

the desired MC/ CD ratio

and consequently the right

tensile strength and elongation

of the final product

Pre-needling and needling

9 is the mechanical bonding

of the fibers through the

use of needlelooms. This

process entangles the fibers

and increases the strength

of the nonwovens

Calendering of the

nonwoven through

oil- heated and cooling

rollers to stabilize the

product, ensure the

texture, stiffness and

thickness required

Accumulation

of the nonwoven

Cutting of nonwoven

and roll winding

Automatic wrapping

of the roll with protective film

Automatic palletizing

and strapping of the rolls

Synthetic fiber: PP, PET, PA, viscose, acrylic, Kevlar, nylon, etc.

Natural fiber: cotton.

| Production capacity: | max. 700 kg/h |

| Working width: | 1.500 mm |

| Fiber length: | 38 - 100 mm |

| Fiber denier: | 1 - 100 Dtex |

| Weighing per minute: | 2 - 6 |

| Weighing error: | max. 1% |

| In-line bale opener: | max. 5 |

Applications

Discover our other turn-key plants