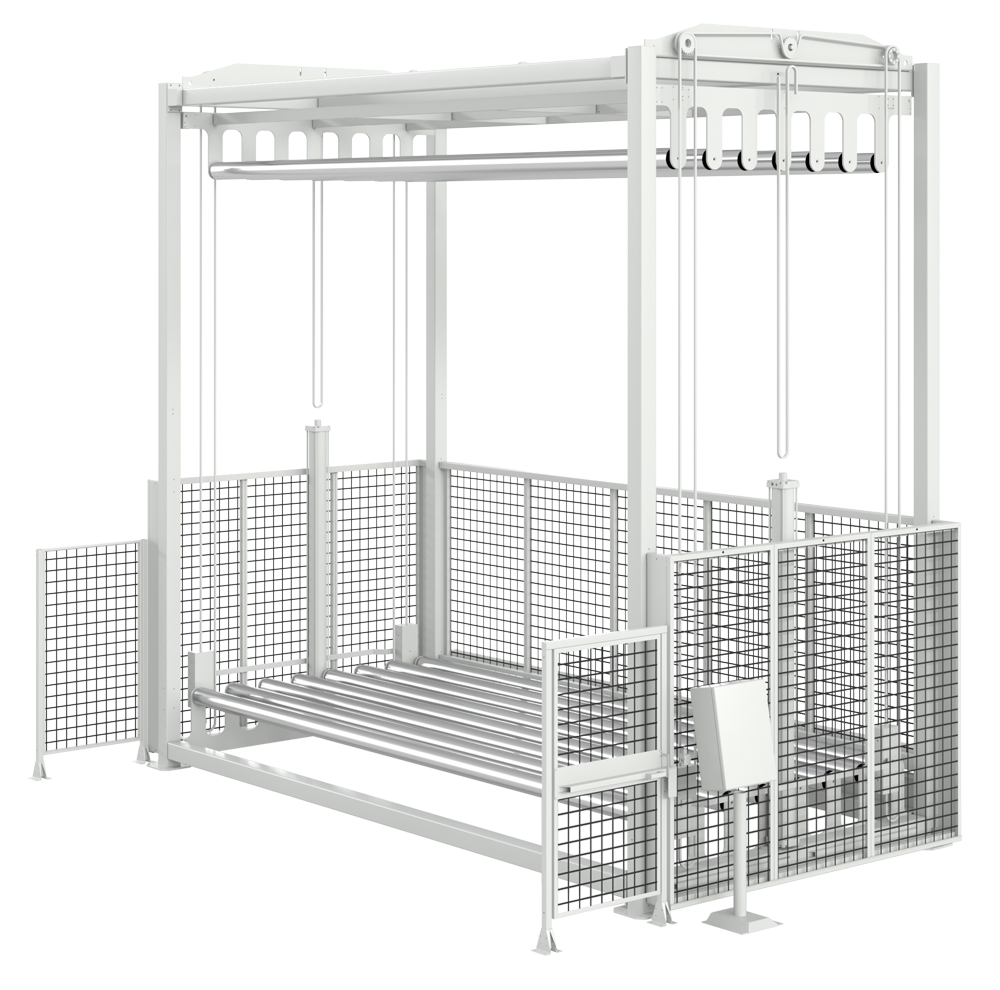

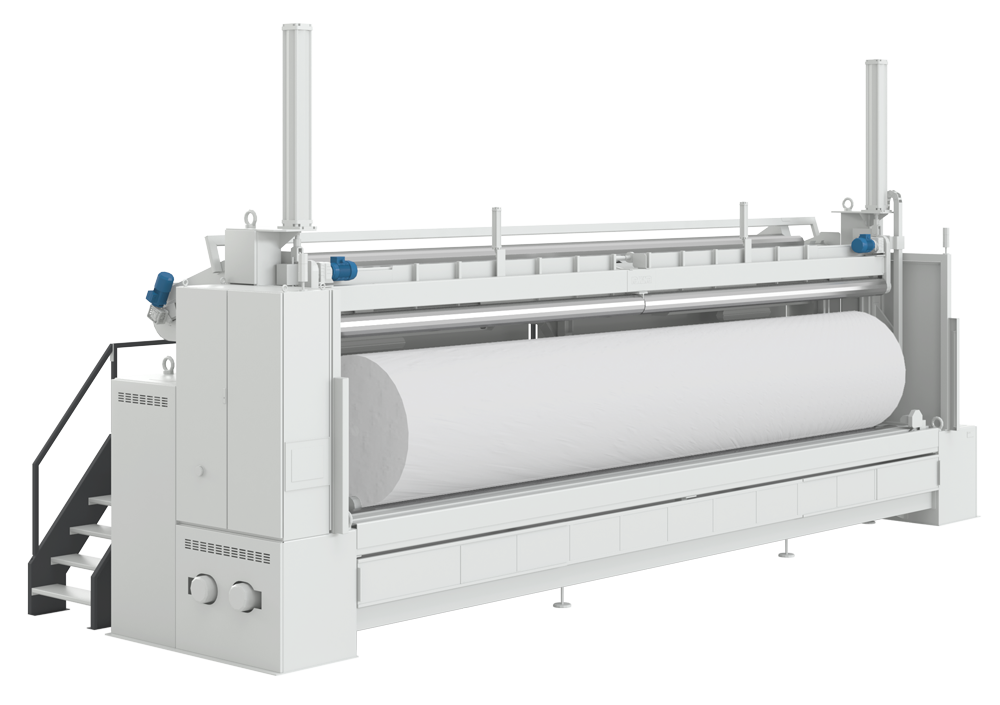

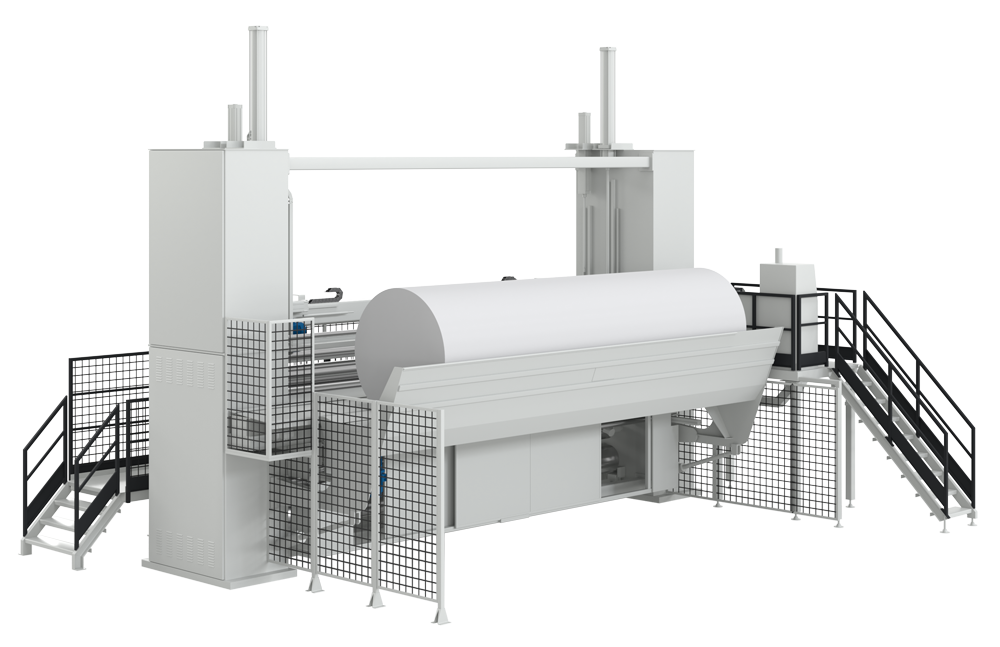

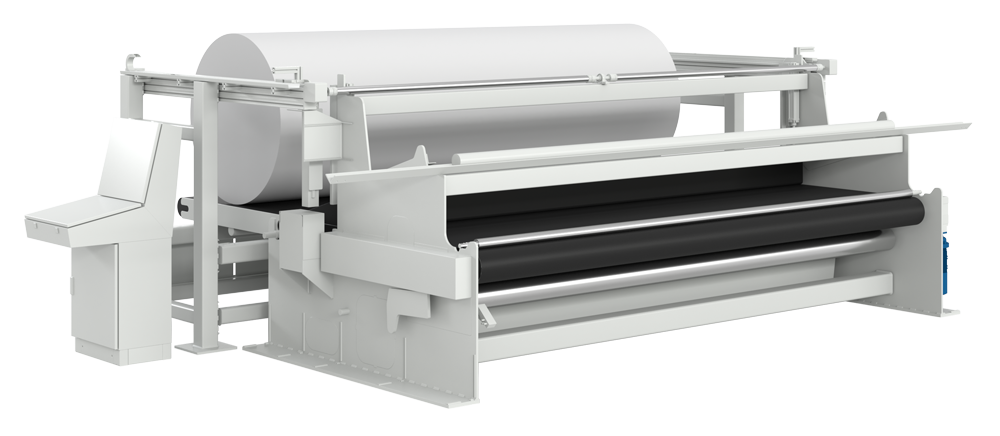

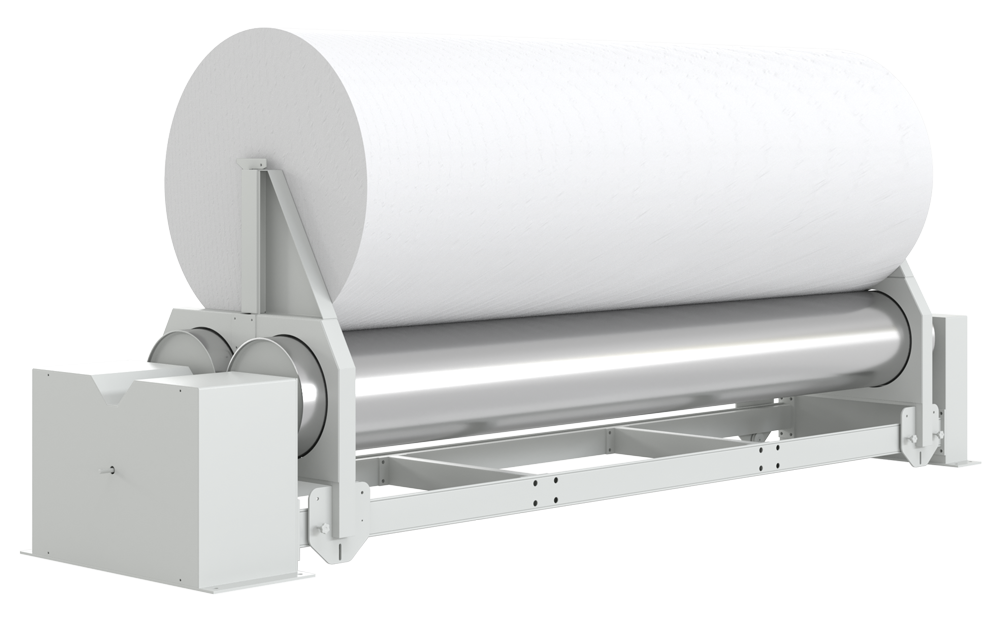

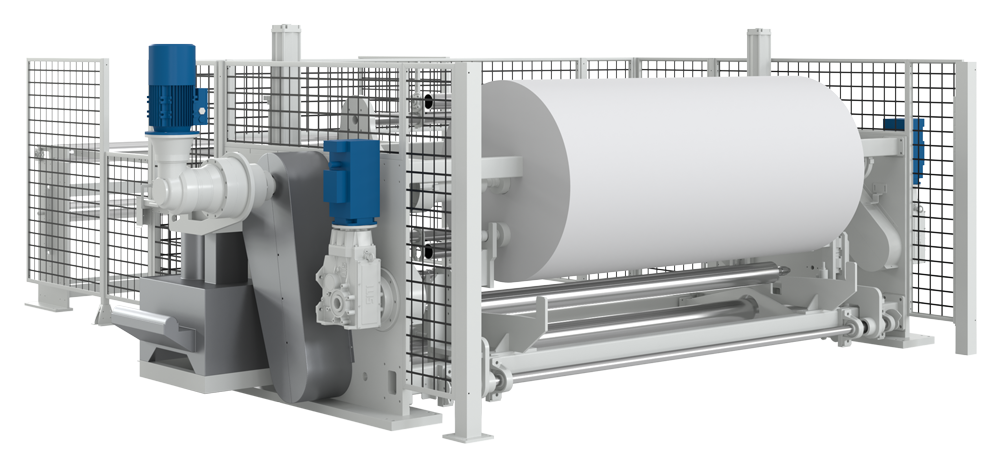

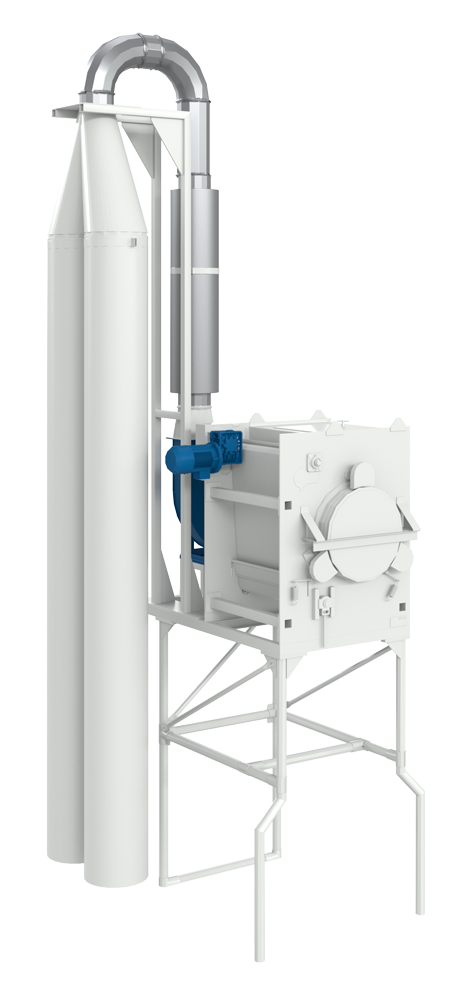

Pneumatic Accumulator

The Pneumatic Accumulator is needed to perform the roll replacement operation without interrupting the production process.

Pressure and tension adjustment

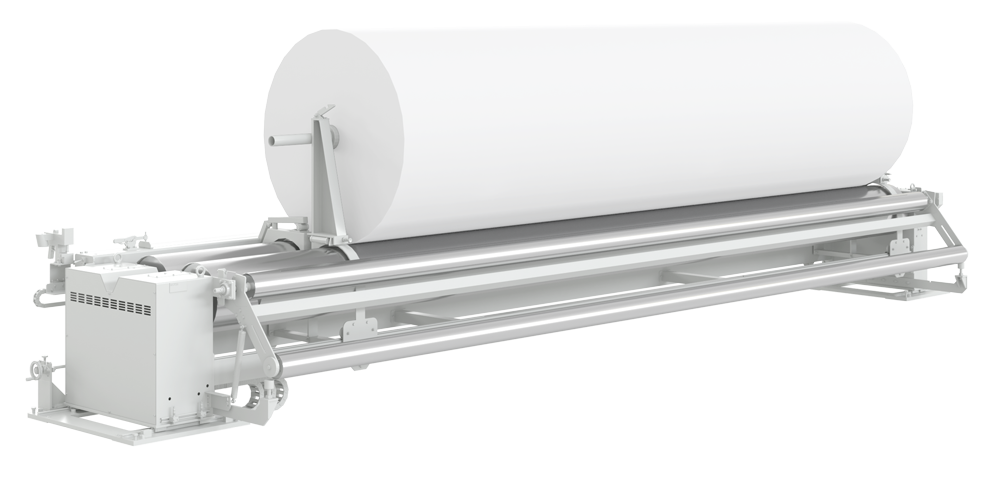

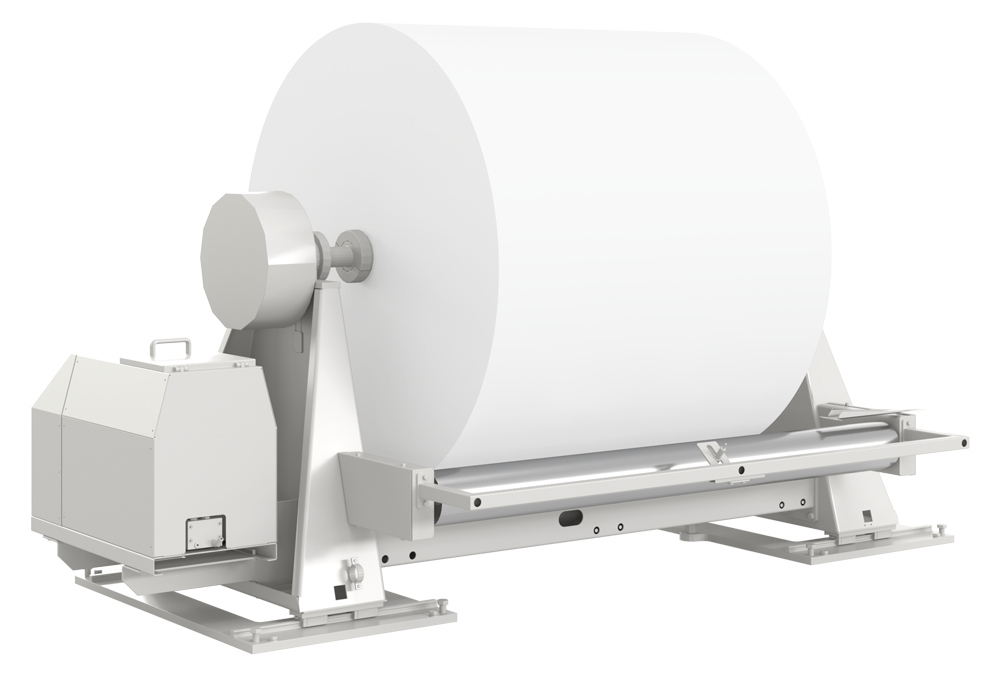

The Pneumatic Accumulator is a very easy-use, reliable and cost-efficient machine designed to accumulate the nonwoven during the change roll operation by simply set at the line starting 4 working pressures (start-working-end-return) according to product width and basic weight. The 4 pressures exercise the regulation of product tensioning and their variation are automatically managed by encoder and proportional valve. During normal winding operation the accumulator’s pneumatic circuit is brought to working pressure, keeping the rollers slightly raised in working position.

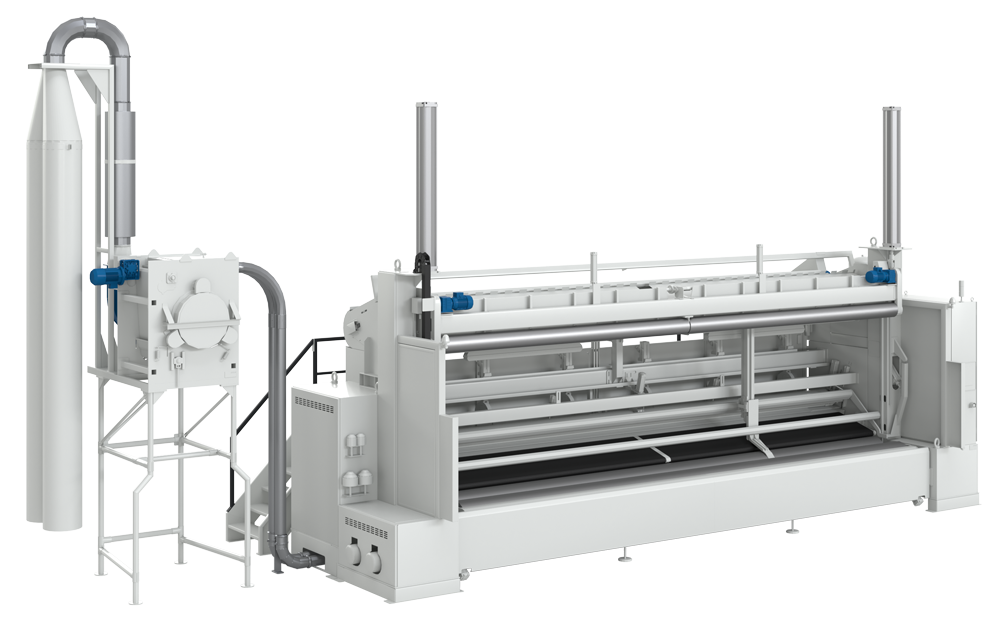

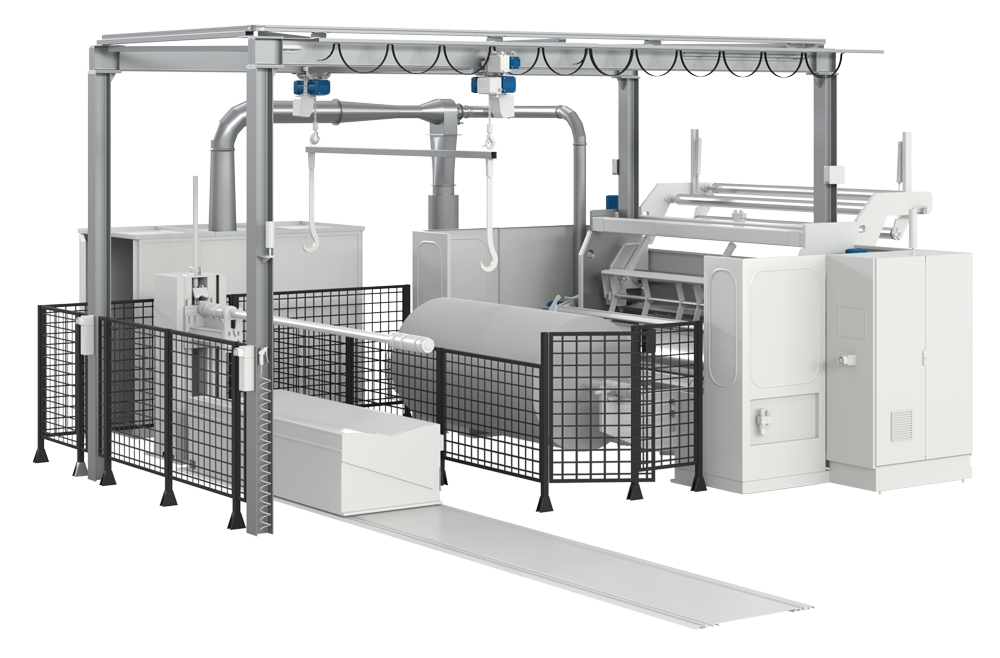

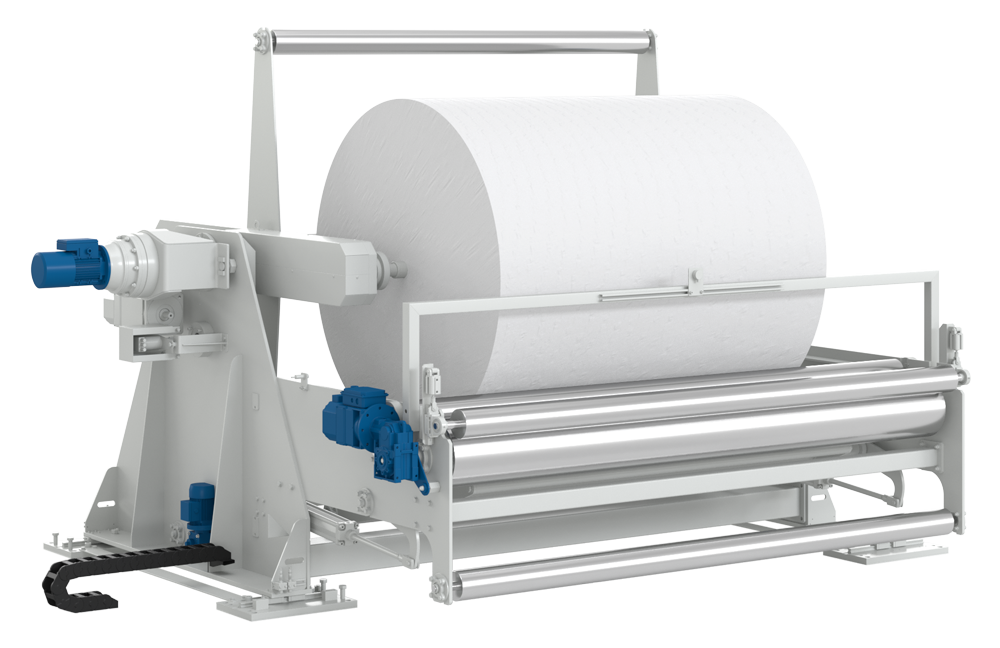

Driven pneumatic accumulator

To operate with lightweight products lower than 100 gsm the Pneumatic Accumulator can be optionally equipped with accumulation rollers driven by belt-transmission to ease product passage and avoid the formation of wrinkles. This simple but smart system represents one of the latest innovation and state-of-the-art technology of Ramina production range that has lately been patented.