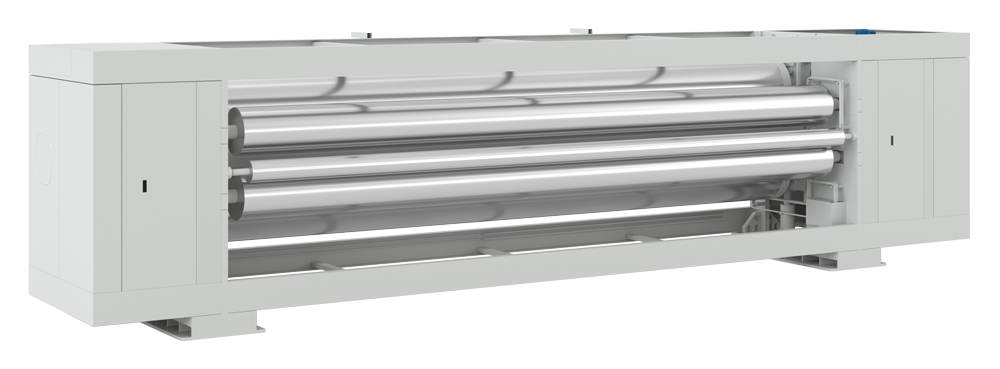

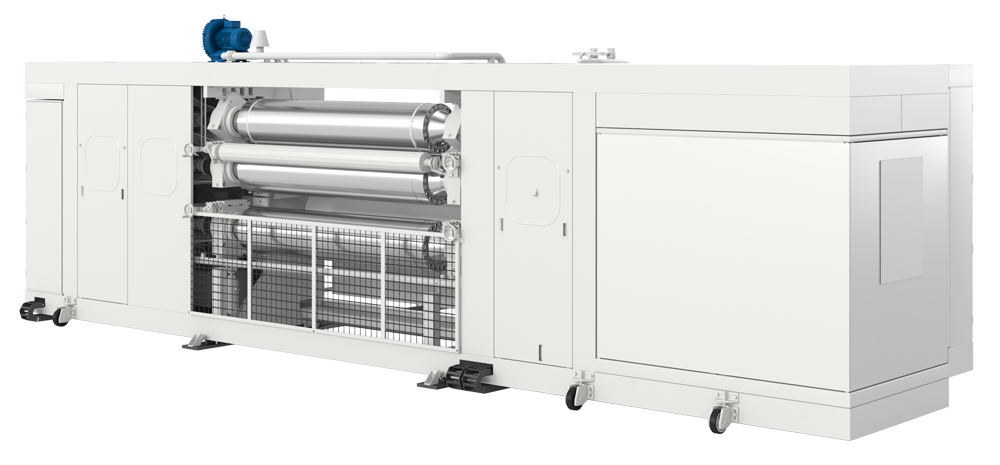

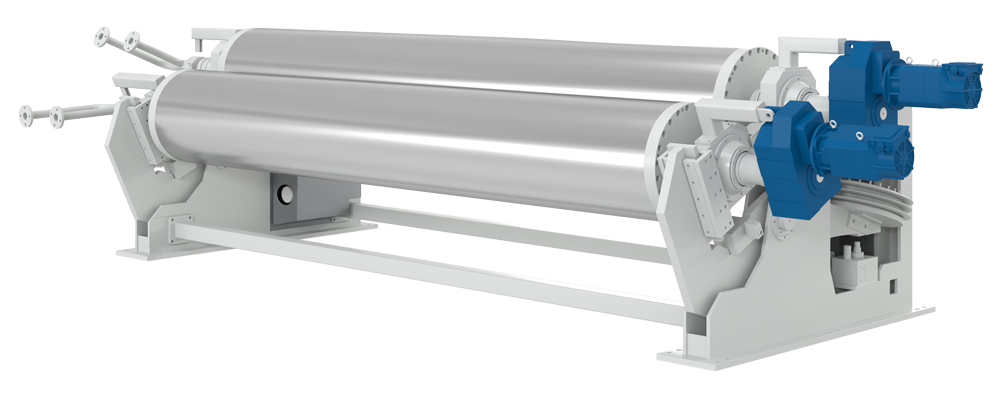

Heating Calender

Ramina high quality heating calenders are designed to stabilize and calibrate the nonwoven after the needling and thermal bonding process. The Heating Calender ensures the texture and reduces the product thickness decreasing the transport volume especially for geotextile, roofing, automotive and filter applications. The standard machine configuration is with 2 or 3 oil-heated rollers and optionally with 2 cooling rollers, however different machine layout can be studied according the customer’s requirement.